RF Solutions

Phone: 01600 719464

- Testimonials

-

Thanks from all of us again for the excellent customer service.

Senior Buyer - Fire Detection Systems

-

Can't believe the fuss this seems to have generated with some suppliers, like they've never seen this type of document! Thank you for your help.

Quality Manager - Cash Protection System

Inspection

The two main industry standard measurements for testing a conductive surface or coating are “sheet resistance” measured using a Low Ohms meter and a ohms per square test block and “Continuity” usually measuring the two furthest points.

These measurements are obtained off the EMC Tested units, known as the “gold sample”, as it has passed the emission tests then the measurement criteria can be made around this, anything better (lower ohmage) will be considered a pass. Several test points can be used to ensure critical areas such as ground plane points or when a conductive gasket is used.

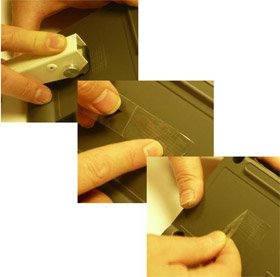

Other testing is usually to check, “Adhesion” and “Cohesion. Measuring adhesion to a substrate and Cohesion, measuring the coating integrity within the layers applied. To carryout these tests we use the standard ASTM tape test and a BS cross hatch test.